The Rise of Automatic Polishing Machine Manufacturers Revolutionizing Surface Finishing Services

In today’s fast-paced manufacturing landscape, the demand for precision and efficiency has propelled the growth of automatic polishing machines. These advanced machines represent a significant leap forward in surface finishing technologies, catering to diverse industries such as automotive, aerospace, electronics, and jewelry. The emergence of numerous automatic polishing machine manufacturers offers an array of services that not only enhance product quality but also streamline production processes.

Understanding Automatic Polishing Machines

Automatic polishing machines are automated equipment designed to achieve high-quality surface finishes on various materials, including metals, plastics, and ceramics. Unlike manual polishing, which can be labor-intensive and inconsistent, these machines provide uniform polishing results, ensuring that each piece meets stringent quality standards. The automation of the polishing process reduces human error, enhances productivity, and ultimately leads to cost savings for manufacturers.

Key Benefits of Automatic Polishing Machines

1. Efficiency and Speed One of the primary advantages of using automatic polishing machines is the speed at which they operate. These machines can polish multiple items simultaneously, significantly increasing throughput. In high-volume production environments, this efficiency translates into shorter lead times and greater customer satisfaction.

2. Consistency and Quality Automatic polishing machines employ precise algorithms and technologies that ensure consistent results across multiple batches. This uniformity is crucial for industries that require high aesthetic standards and reliable product performance. As a result, manufacturers can minimize defects and reduce waste.

3. Labor Cost Reduction By automating the polishing process, companies can reduce their reliance on manual labor. This not only cuts down on labor costs but also allows skilled workers to focus on more complex tasks, thereby maximizing the overall productivity of the workforce.

4. Adaptability Modern automatic polishing machines are designed to handle various materials and surface finishes. This adaptability makes them an attractive option for manufacturers who deal with diverse products and need to switch between different polishing requirements quickly.

5. Data-Driven Improvements Many automatic polishing machines are equipped with sensors and software that provide real-time data on performance metrics. This data can be analyzed to optimize the polishing process further, leading to continuous improvement initiatives and better resource management.

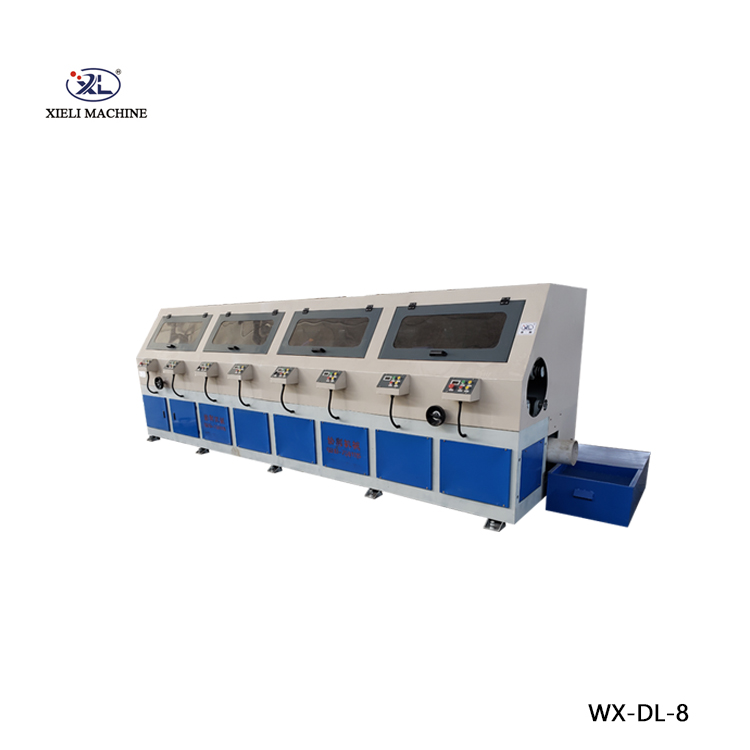

automatic polishing machine manufacturers service

Challenges Faced by Manufacturers

Despite the numerous benefits, the proliferation of automatic polishing machines presents some challenges for manufacturers. The initial investment cost can be significant, requiring careful financial planning. Additionally, integrating new technology into existing workflows can necessitate changes in processes and staff training. Manufacturers must also stay abreast of maintenance needs to ensure longevity and optimal performance of the machinery.

The Role of Manufacturers in Service Delivery

Automatic polishing machine manufacturers play a critical role in the overall service delivery ecosystem. They not only design and produce machines but also provide essential services such as installation, maintenance, and training. A reputable manufacturer will offer comprehensive support throughout the machine's lifecycle, ensuring that clients can maximize their investment.

1. Technical Support Leading manufacturers offer technical support to assist clients in troubleshooting issues that may arise during operation. This support can prevent prolonged downtimes, thereby maintaining efficiency within the production environment.

2. Training Programs To effectively use these sophisticated machines, training programs are vital. Manufacturers often provide on-site and virtual training sessions to equip users with the necessary skills and knowledge for optimal operation.

3. Customized Solutions Understanding that different industries have unique needs, many manufacturers offer customized polishing solutions. Whether it’s adjusting the machine to handle specific materials or modifying the polishing process to meet particular aesthetic requirements, customization is key to customer satisfaction.

The Future of Automatic Polishing Machines

Looking ahead, the automatic polishing machine industry is poised for continued growth. Innovations in technology, such as artificial intelligence and machine learning, are likely to enhance the capabilities of these machines further. With an increasing focus on sustainability, manufacturers are also exploring eco-friendly polishing materials and processes, aligning with global initiatives to promote environmental responsibility.

In conclusion, the role of automatic polishing machine manufacturers in enhancing surface finishing services cannot be overstated. By providing advanced machinery and comprehensive support, these manufacturers are not only transforming production capabilities but also driving the future of manufacturing. As industries strive for greater efficiency and quality, the importance of these machines will only continue to rise.

-

Discount High-Precision Surface Polishing Machine Durable & EfficientNewsApr.29,2025

-

High-Precision SS Square Tube Polishing Machine China SupplierNewsApr.29,2025

-

Stainless Steel Square Pipe Polishing Machine OEM & High-EfficiencyNewsApr.28,2025

-

Centerless Grinder Troubleshooting Fast Fix for OEM, China & Discount ModelsNewsApr.28,2025

-

Centerless Grinder Automation Solutions OEM & Precision Systems ChinaNewsApr.28,2025

-

Scarlo Centerless Grinder OEM High-Precision China Models & DiscountsNewsApr.28,2025