The Importance of Surface Polishing Machines in Modern Manufacturing

In the contemporary manufacturing landscape, the significance of surface polishing machines cannot be overstated

. These machines play a crucial role in enhancing the aesthetic and functional properties of various materials, thus making them indispensable in industries ranging from automotive to aerospace and consumer electronics.Surface polishing involves the removal of imperfections and the refinement of a surface's texture to achieve a desired finish. This process not only improves the visual appeal of a product but also contributes to its overall performance. For instance, a well-polished surface can reduce friction, improve corrosion resistance, and enhance the product's lifespan. This is particularly important in sectors where precision and durability are paramount.

Famous manufacturers of surface polishing machines have developed technologies that cater to a wide range of materials, including metals, plastics, and ceramics. These machines utilize various polishing techniques such as mechanical polishing, chemical polishing, and electrochemical polishing. Each method serves specific applications and yields different results, allowing manufacturers to choose the technique that best suits their needs.

One of the most recognized names in surface polishing technology is the Siemens AG company, known for its innovative manufacturing solutions. Siemens surface polishing machines incorporate advanced automation and precision engineering, catering to both high-volume production requirements and bespoke applications. Their machines are engineered to deliver consistent results, minimizing the need for manual labor and reducing the risk of human error.

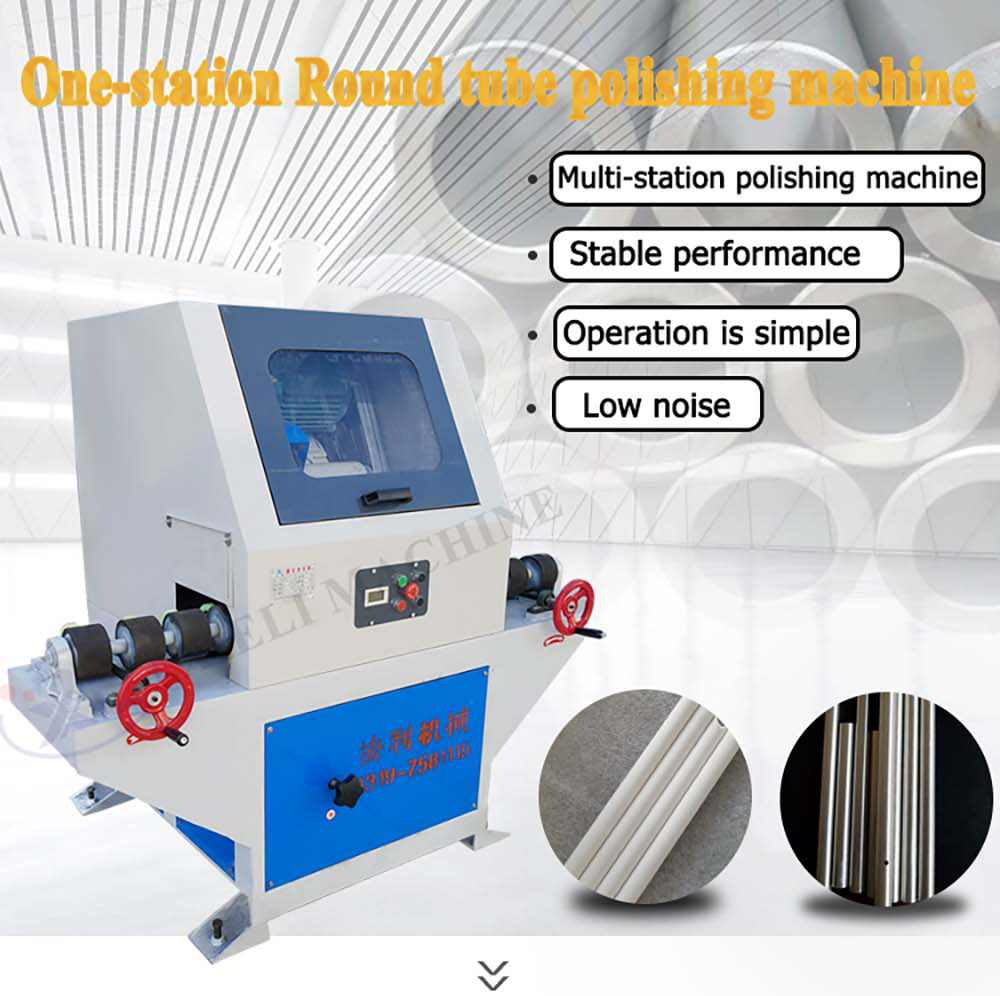

famous surface polishing machine

Another pivotal player in the industry is 3M, a company renowned for its abrasive products. 3M's surface polishing machines utilize a combination of specialized abrasives and advanced technology to ensure an optimal finish. Their machines are designed for versatility, allowing manufacturers to polish a variety of materials while maintaining stringent quality control.

In addition to enhancing aesthetic qualities, renowned surface polishing machines contribute significantly to safety and performance. For instance, in the automotive industry, the smoothness of critical components like gears and bearings is vital. A polished surface can lead to improved engine efficiency and reduced wear over time. Moreover, in the aerospace sector, polished parts are essential for performance, as any minor imperfections can lead to catastrophic failures.

The demand for surface polishing machines has surged in recent years as industries strive for higher quality standards and increased production efficiency. The global focus on sustainability is also driving innovation in this sector. Many manufacturers are now developing eco-friendly polishing solutions that minimize waste and reduce environmental impact. This shift aligns with the broader trend towards sustainable manufacturing practices, where both efficiency and environmental stewardship are prioritized.

Furthermore, advancements in technology, such as artificial intelligence and machine learning, are influencing the design and operation of surface polishing machines. These technologies enable real-time monitoring and control of the polishing process, ensuring optimal results while reducing downtime and material waste. As these technologies evolve, the capabilities of surface polishing machines are expected to expand, providing manufacturers with even greater flexibility and efficiency.

In conclusion, surface polishing machines are essential tools in modern manufacturing, providing not only aesthetic enhancements but also functional improvements across various industries. With leading manufacturers continuously innovating and adapting to the changing landscape, these machines will remain pivotal in driving quality standards, operational efficiency, and sustainability in the years to come. As industries continue to evolve, the demand for advanced surface polishing solutions will undoubtedly grow, further solidifying the role of these machines in the manufacturing process.

-

Discount High-Precision Surface Polishing Machine Durable & EfficientNewsApr.29,2025

-

High-Precision SS Square Tube Polishing Machine China SupplierNewsApr.29,2025

-

Stainless Steel Square Pipe Polishing Machine OEM & High-EfficiencyNewsApr.28,2025

-

Centerless Grinder Troubleshooting Fast Fix for OEM, China & Discount ModelsNewsApr.28,2025

-

Centerless Grinder Automation Solutions OEM & Precision Systems ChinaNewsApr.28,2025

-

Scarlo Centerless Grinder OEM High-Precision China Models & DiscountsNewsApr.28,2025