Exploring the Role of Paragon RC-12 Centerless Grinders in Global Exports

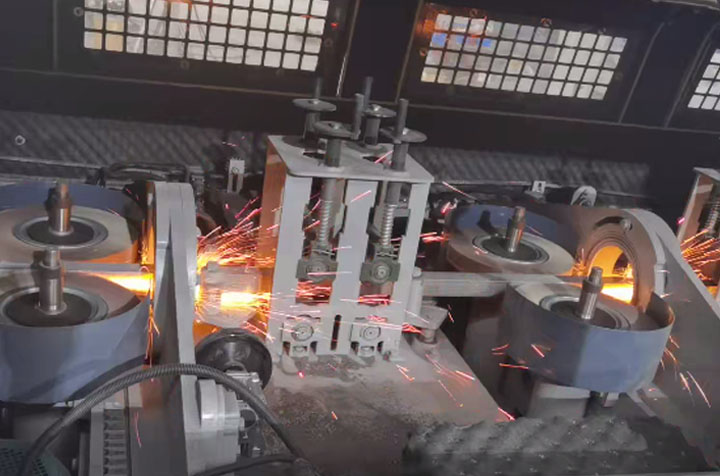

In the world of precision machining, the Paragon RC-12 Centerless Grinder has carved a niche for itself as a powerful tool for manufacturers seeking efficiency and accuracy. As industries evolve and global competition intensifies, the demand for high-quality centerless grinding machines continues to rise. This article delves into the features, benefits, and role of Paragon RC-12 centerless grinders in the realm of exports.

Exploring the Role of Paragon RC-12 Centerless Grinders in Global Exports

One of the key advantages of the Paragon RC-12 is its versatility. It can be easily adjusted to accommodate different part sizes and shapes, making it suitable for a wide array of applications across various industries, from automotive to aerospace. This adaptability not only helps manufacturers reduce downtime but also facilitates the production of diverse product lines without requiring significant reconfiguration.

paragon rc-12 centerless grinder exporters

As a result of these advantages, the Paragon RC-12 has gained traction among exporters looking to expand their reach into international markets. The machine’s reputation for reliability and precision aligns well with the demands of global clients who prioritize quality and efficiency in their manufacturing processes. Exporters can leverage the Paragon RC-12 as a competitive advantage, showcasing their ability to deliver high-quality, precision-engineered components to clients worldwide.

Moreover, the increase in automation and the push for Industry 4.0 has further enhanced the appeal of the Paragon RC-12. Modern manufacturing facilities are increasingly adopting smart technologies, and this grinder can easily integrate into automated systems. This capability not only streamlines production processes but also enhances data collection for improved quality control and decision-making. As a result, exporters featuring the Paragon RC-12 in their offerings can attract more technologically advanced partners and clients.

In conclusion, the Paragon RC-12 Centerless Grinder represents a significant asset for manufacturers and exporters in the global marketplace. Its advanced features, coupled with its versatility and reliability, make it an ideal choice for high-precision applications. As industries continue to grow and evolve, the Paragon RC-12 is poised to play a crucial role in helping manufacturers meet the demands of modern production while boosting their export potential. With this grinder in their arsenal, businesses can ensure that they remain competitive and responsive to the dynamic needs of global markets.