чэрв . 22, 2024 01:54

Back to list

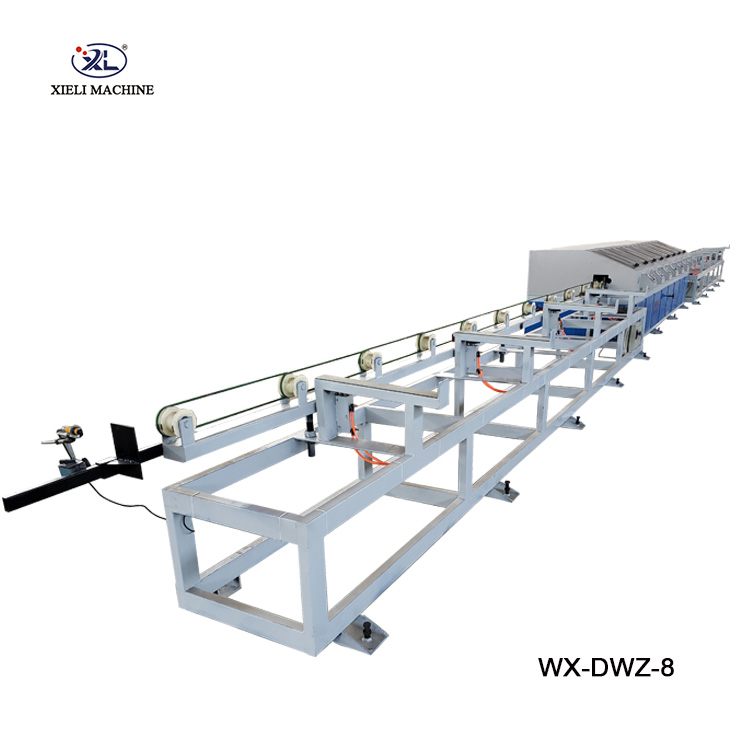

ODM Centerless Grinder Tables Overview

The Efficiency and Precision of ODMT Centerless Grinder Tables

In the world of manufacturing, precision and efficiency are paramount. One tool that stands out for its ability to deliver both is the ODMT centerless grinder table. This specialized equipment has revolutionized the way metal parts are processed, offering unparalleled accuracy and consistency in a high-speed production environment.

The ODMT centerless grinder table operates on the principle of centerless grinding, a method that eliminates the need for centering workpieces before grinding. Unlike traditional grinding machines that require parts to be precisely mounted on centers or between two points, centerless grinders use a combination of a grinding wheel, a regulating wheel, and a support blade to hold and rotate the workpiece. This setup allows for continuous throughfeed grinding, significantly reducing setup time and increasing productivity.

The design of the ODMT centerless grinder table is optimized for this process. It features a robust construction that ensures stability during operation, even at high speeds. The table's flat surface is precisely machined to provide a reliable reference for the support blade, which is crucial for maintaining consistent depth of cut. Additionally, the table is often equipped with adjustable fixtures or attachments that can be customized to handle various shapes and sizes of parts, making it versatile for different grinding applications.

One of the key benefits of using an ODMT centerless grinder table is its capability to achieve uniform dimensions and surface finishes

One of the key benefits of using an ODMT centerless grinder table is its capability to achieve uniform dimensions and surface finishes One of the key benefits of using an ODMT centerless grinder table is its capability to achieve uniform dimensions and surface finishes

One of the key benefits of using an ODMT centerless grinder table is its capability to achieve uniform dimensions and surface finishes

One of the key benefits of using an ODMT centerless grinder table is its capability to achieve uniform dimensions and surface finishes

One of the key benefits of using an ODMT centerless grinder table is its capability to achieve uniform dimensions and surface finishes odm centerless grinder tables. As the workpiece moves through the machine, it is ground evenly on all sides, resulting in a high level of roundness and dimensional accuracy. This is particularly important in industries where tight tolerances are required, such as in the production of bearings, gears, and other critical components.

Furthermore, the automation potential of centerless grinder tables makes them ideal for integration into advanced manufacturing systems. With the appropriate controls and accessories, these machines can be programmed to perform complex grinding tasks with minimal human intervention. This not only reduces labor costs but also limits the potential for human error, ensuring a higher quality end product.

In conclusion, the ODMT centerless grinder table represents a pinnacle of modern manufacturing technology. Its streamlined process, precision engineering, and adaptability make it an essential piece of equipment for any factory striving for excellence in their grinding operations. By leveraging the power of centerless grinding technology, manufacturers can enhance their workflows, improve product quality, and stay competitive in today's fast-paced industrial landscape.

odm centerless grinder tables. As the workpiece moves through the machine, it is ground evenly on all sides, resulting in a high level of roundness and dimensional accuracy. This is particularly important in industries where tight tolerances are required, such as in the production of bearings, gears, and other critical components.

Furthermore, the automation potential of centerless grinder tables makes them ideal for integration into advanced manufacturing systems. With the appropriate controls and accessories, these machines can be programmed to perform complex grinding tasks with minimal human intervention. This not only reduces labor costs but also limits the potential for human error, ensuring a higher quality end product.

In conclusion, the ODMT centerless grinder table represents a pinnacle of modern manufacturing technology. Its streamlined process, precision engineering, and adaptability make it an essential piece of equipment for any factory striving for excellence in their grinding operations. By leveraging the power of centerless grinding technology, manufacturers can enhance their workflows, improve product quality, and stay competitive in today's fast-paced industrial landscape.

One of the key benefits of using an ODMT centerless grinder table is its capability to achieve uniform dimensions and surface finishes

One of the key benefits of using an ODMT centerless grinder table is its capability to achieve uniform dimensions and surface finishes

One of the key benefits of using an ODMT centerless grinder table is its capability to achieve uniform dimensions and surface finishes

One of the key benefits of using an ODMT centerless grinder table is its capability to achieve uniform dimensions and surface finishes odm centerless grinder tables. As the workpiece moves through the machine, it is ground evenly on all sides, resulting in a high level of roundness and dimensional accuracy. This is particularly important in industries where tight tolerances are required, such as in the production of bearings, gears, and other critical components.

Furthermore, the automation potential of centerless grinder tables makes them ideal for integration into advanced manufacturing systems. With the appropriate controls and accessories, these machines can be programmed to perform complex grinding tasks with minimal human intervention. This not only reduces labor costs but also limits the potential for human error, ensuring a higher quality end product.

In conclusion, the ODMT centerless grinder table represents a pinnacle of modern manufacturing technology. Its streamlined process, precision engineering, and adaptability make it an essential piece of equipment for any factory striving for excellence in their grinding operations. By leveraging the power of centerless grinding technology, manufacturers can enhance their workflows, improve product quality, and stay competitive in today's fast-paced industrial landscape.

odm centerless grinder tables. As the workpiece moves through the machine, it is ground evenly on all sides, resulting in a high level of roundness and dimensional accuracy. This is particularly important in industries where tight tolerances are required, such as in the production of bearings, gears, and other critical components.

Furthermore, the automation potential of centerless grinder tables makes them ideal for integration into advanced manufacturing systems. With the appropriate controls and accessories, these machines can be programmed to perform complex grinding tasks with minimal human intervention. This not only reduces labor costs but also limits the potential for human error, ensuring a higher quality end product.

In conclusion, the ODMT centerless grinder table represents a pinnacle of modern manufacturing technology. Its streamlined process, precision engineering, and adaptability make it an essential piece of equipment for any factory striving for excellence in their grinding operations. By leveraging the power of centerless grinding technology, manufacturers can enhance their workflows, improve product quality, and stay competitive in today's fast-paced industrial landscape. Latest news

-

Discount High-Precision Surface Polishing Machine Durable & EfficientNewsApr.29,2025

-

High-Precision SS Square Tube Polishing Machine China SupplierNewsApr.29,2025

-

Stainless Steel Square Pipe Polishing Machine OEM & High-EfficiencyNewsApr.28,2025

-

Centerless Grinder Troubleshooting Fast Fix for OEM, China & Discount ModelsNewsApr.28,2025

-

Centerless Grinder Automation Solutions OEM & Precision Systems ChinaNewsApr.28,2025

-

Scarlo Centerless Grinder OEM High-Precision China Models & DiscountsNewsApr.28,2025