Choosing the Right CNC Centerless Grinder A Guide to Manufacturers

When it comes to precision machining, few tools are as integral as the CNC centerless grinder. This sophisticated piece of machinery is designed to grind cylindrical parts without the need for a center, thereby enabling a high degree of accuracy and efficiency. As industries evolve, the demand for high-quality CNC centerless grinders is on the rise, prompting businesses to consider various manufacturers. In this article, we will explore key factors to consider when buying a CNC centerless grinder and highlight some notable manufacturers in the field.

Understanding CNC Centerless Grinders

A CNC centerless grinder operates on a simple yet effective principle. The workpiece is held in place by two wheels the grinding wheel and the regulating wheel. Unlike traditional grinders that need to secure a workpiece at both ends, centerless grinders allow for continuous feeding, which enhances throughput and reduces production times. Moreover, they are particularly advantageous for processing large batches of similar parts.

Key Features to Consider

1. Precision and Accuracy The primary function of any grinder is to deliver precision. It's essential to evaluate the manufacturer's specifications regarding accuracy, travel, and tolerances. Look for CNC centerless grinders that offer tight tolerances of 0.0001 inches or better.

2. Machine Size and Design Depending on the size of the parts you intend to grind, selecting the appropriate machine size is crucial. Some manufacturers offer compact models suitable for smaller workshops, while others provide larger machines designed for industrial-scale operations.

3. Ease of Use A user-friendly interface can significantly enhance productivity. Ensure that the CNC centerless grinder features an intuitive control system that can be easily operated by your team.

4. Automation Features Many modern centerless grinders come equipped with automated features like automatic load and unload systems, which can minimize manual intervention and increase efficiency.

5. Durability and Maintenance Investing in a durable machine is paramount, as it can withstand extensive use over time. Also, consider manufacturers that offer comprehensive support and maintenance services to prolong the life of your grinder.

buy cnc centerless grinder manufacturers

6. Price and Value While budgeting for a CNC centerless grinder, remember that the cheapest option may not always provide the best value. Assess the overall features and the long-term benefits when making a decision.

Leading Manufacturers

As you embark on your search for a CNC centerless grinder, it’s helpful to consider some of the most reputable manufacturers in the industry

1. Royal Master Grinders Known for their innovative approach, Royal Master Grinders has been a pioneer in CNC centerless grinding technology. They offer a range of models tailored for different applications, emphasizing precision and ease of use.

2. Cincinnati Grinders With a rich history and a strong reputation, Cincinnati Grinders manufactures some of the most reliable CNC centerless grinders. Their machines are renowned for their sturdy build and advanced controls.

3. Koyo Machinery USA Koyo focuses on providing custom solutions for various industries. They specialize in high-production centerless grinding and have a wide array of models available, ensuring there is something for every need.

4. Okuma Okuma’s CNC centerless grinders are known for their advanced technology and software integration. Their machines frequently incorporate IoT capabilities, allowing for remote monitoring and management.

5. TGS (Tianjin Gije) Grinding Machines TGS combines cutting-edge technology with affordability. Their CNC centerless grinders are perfect for small to medium-sized operations looking for reliable performance without breaking the bank.

Conclusion

Investing in a CNC centerless grinder is a significant decision that requires careful consideration of various factors, including precision, design, automation features, and overall cost. By understanding what to look for and exploring options from reputable manufacturers, you can select a machine that aligns perfectly with your business needs. As technology continues to advance, staying informed about the latest innovations in CNC centerless grinding will benefit your operation in the long run, helping to maximize efficiency and productivity.

-

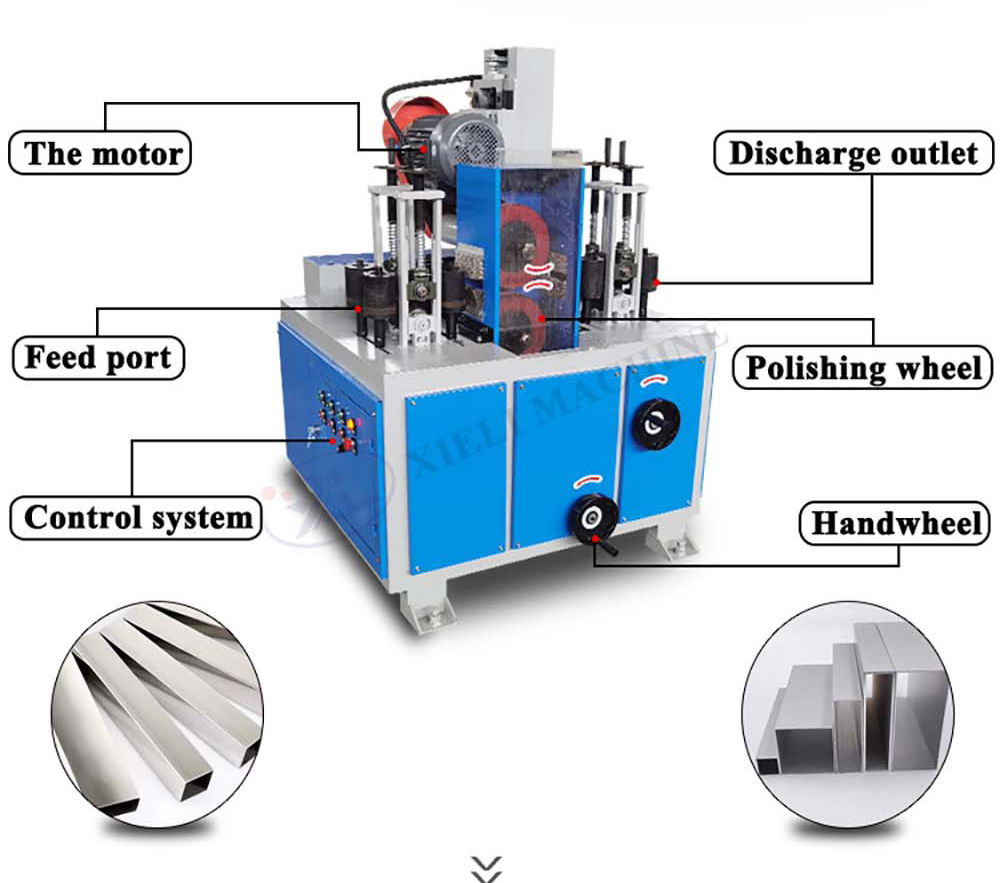

Discount High-Precision Surface Polishing Machine Durable & EfficientNewsApr.29,2025

-

High-Precision SS Square Tube Polishing Machine China SupplierNewsApr.29,2025

-

Stainless Steel Square Pipe Polishing Machine OEM & High-EfficiencyNewsApr.28,2025

-

Centerless Grinder Troubleshooting Fast Fix for OEM, China & Discount ModelsNewsApr.28,2025

-

Centerless Grinder Automation Solutions OEM & Precision Systems ChinaNewsApr.28,2025

-

Scarlo Centerless Grinder OEM High-Precision China Models & DiscountsNewsApr.28,2025